€19.75*

Available, delivery time: 1-3 days

Kurzbeschreibung: ColuxGlow afterglow screen printing ink (print)

Field of application

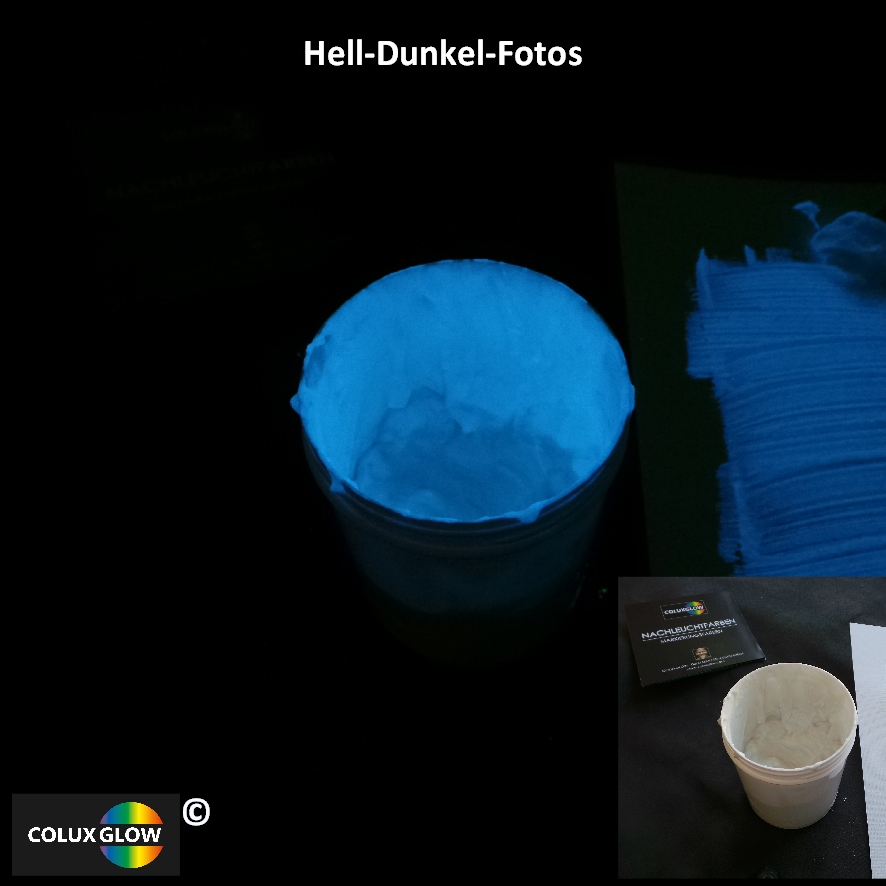

ColuxGlow Screen Printing Ink Textile afterglow blue transparent

Water based screen printing ink textile afterglow blue for printing on cotton and synthetic fabrics made of polyester, nylon.

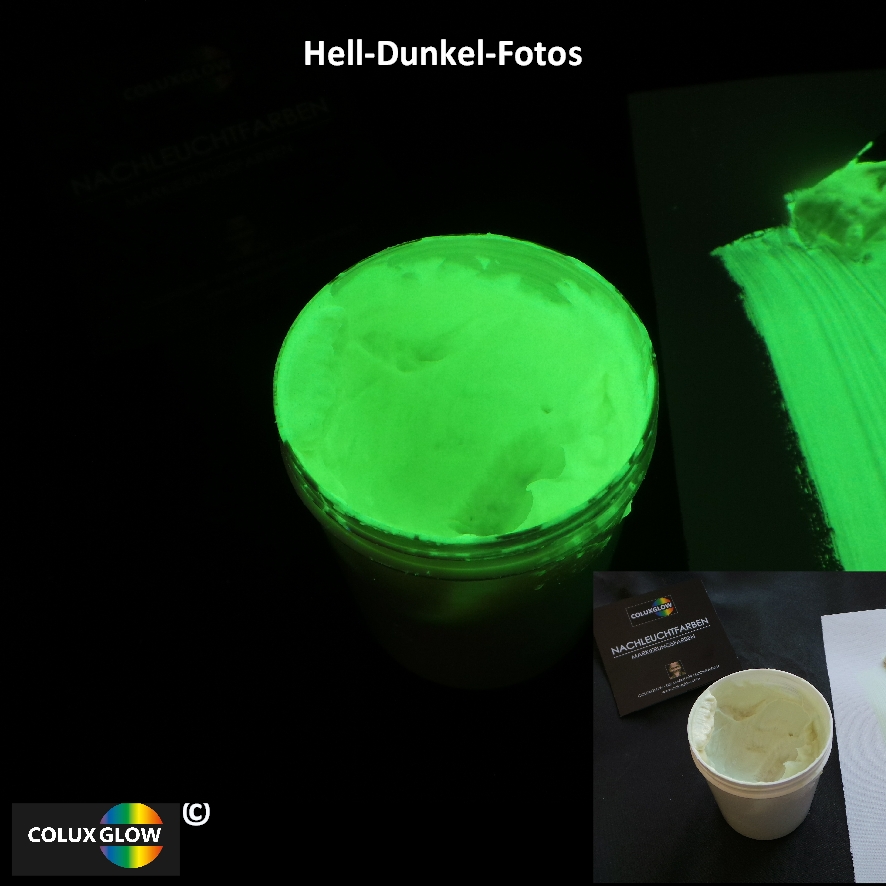

WHAT CAN COLUXGLOW INK DO?

ColuxGlow afterglow screen printing ink textile is a water-based textile printing ink for printing on cotton and synthetic fabrics made of polyester, nylon.

BRIEF DESCRIPTION

ColuxGlow water-based ink system afterglow screen printing ink textile, free of petrol, solvents and formaldehyde. Contains no banned substances according to Ökotex standard and is free from THM Annex 38.

APPLICATION

■ ColuxGlow textile is a ready-to-print textile ink. Thinning, if necessary, is possible by adding a special thinner. Do not dilute with water. Water separates the pigments from the system.

■ Depending on the print motif and substrate, PES or polyester fabrics of 21-45 threads/cm are used. The printing stencil must have a water-resistant screen emulsion. Classic textile permanent stencils are suitable

■ ColuxGlow textile dries both in the air at room temperature (approx. 15-20 min.) and under hot air and IR exposure in textile dryers. The drying time depends on the absorbency of the textile substrate.

■ Heat fix only coloured inks: After the ink has dried at room temperature, the prints are heat set for approx. 1 min. at 150° C hot air or hot press or iron and baking paper. (Step omitted for transparent inks)

NOTE

A plastisol background print is unsuitable! Simply clean the screen with water and dissolve dried ink residues with ethyl acetate.

SPECIFICATION

| FUNCTION | Screen printing ink for luminous motifs | |

| COLOUR TONE | transparent blue photoluminescent | |

| DENSITY | 1,2 g/l | |

| LAYER | 21-45 mesh screen | |

| CONSUMPTION | 10 sqm / litre | |

| APPLICATION | not dilutable, for cotton and polyester and nylon | |

| PRINTING TECHNOLOGY | Screen printing | |

| PROCESSING | 15-20 minutes drying, then heat fix - not applicable for transparent grades. | |

| DRYING TIME | PRINTING | 15-20 min. |

| UNDERPRINTING/OVERPRINTING | NOT SUITABLE | |

| WASH RESISTANT | 12 hours or after fixation | |

| PACKAGING | 200 ml and 1 litre cans | |

| SHELF LIFE | Use up ink within 12 months - stir before use. | |

SPEZIFIKATION

| FUNKTION | Siebdruckfarbe für Leuchtmotive | |

| FARBTON | transparent blau nachleuchtend | |

| DICHTE | 1,2 g/l | |

| SCHICHT | 21-45 Maschen Sieb | |

| VERBRAUCH | 10 qm / Liter | |

| ANWENDUNG | nicht verdünnbar, für Baumwolle und Polyester und Nylon | |

| DRUCKTECHNIK | Siebdruck | |

| VERARBEITUNG | 15-20 Minuten Trocknung, dann heiß fixieren - entfällt bei transparenten Sorten. | |

| TROCKENZEIT | ANDRUCK | 15-20 Min. |

| UNTERDRUCKEN/ ÜBERDRUCKEN | NICHT GEEIGNET | |

| WASCHFEST | 12 Stunden bzw. nach Fixierung | |

| VERPACKUNG | Dosen 200 ml und 1 Liter | |

| LAGERFÄHIGKEIT/HALTBARKEIT | Druckfarbe innerhabl 12 Monate aufbrauchen - vor Gebruach aufrühren. | |

Login