€2.99*

Available, delivery time: 1-3 days

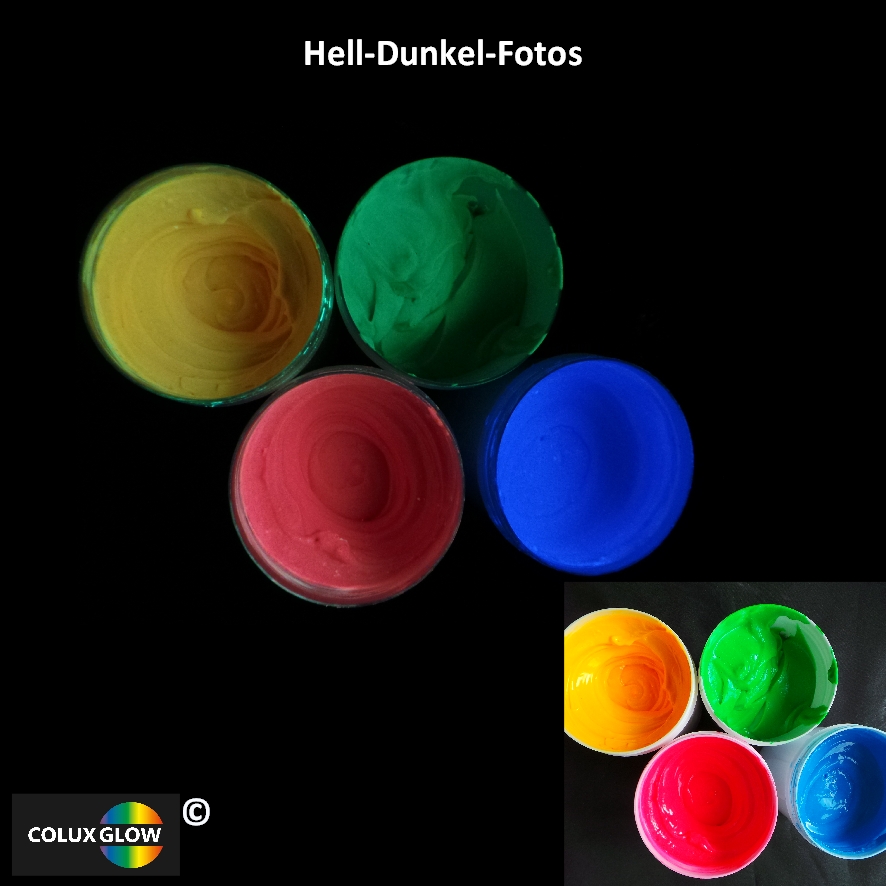

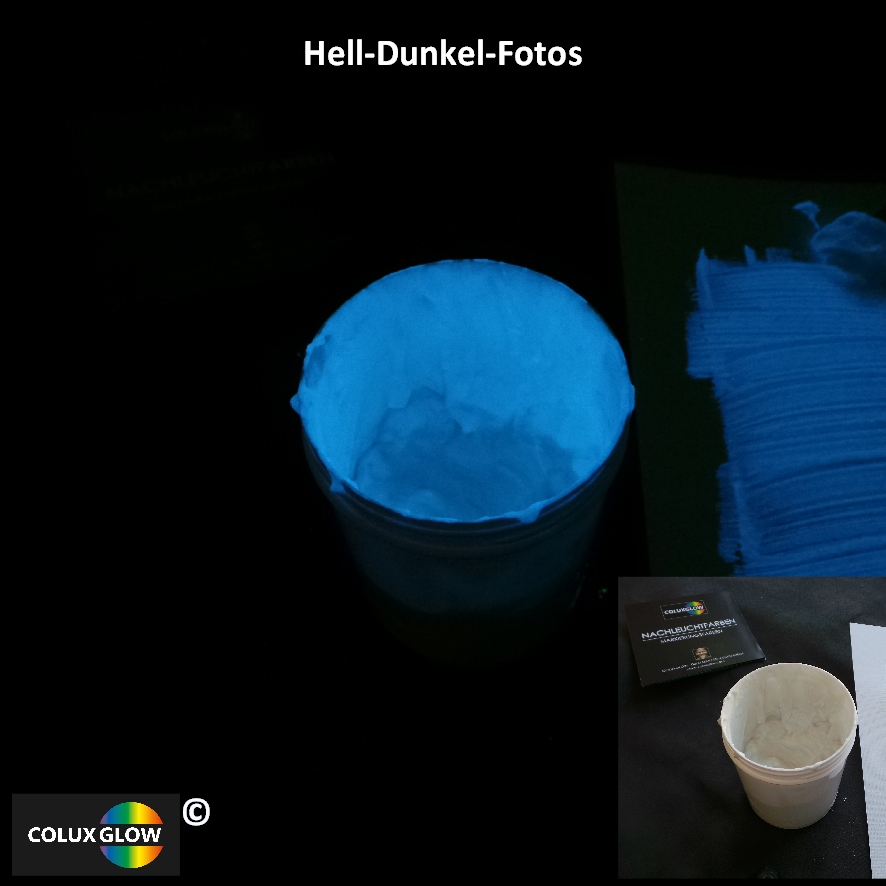

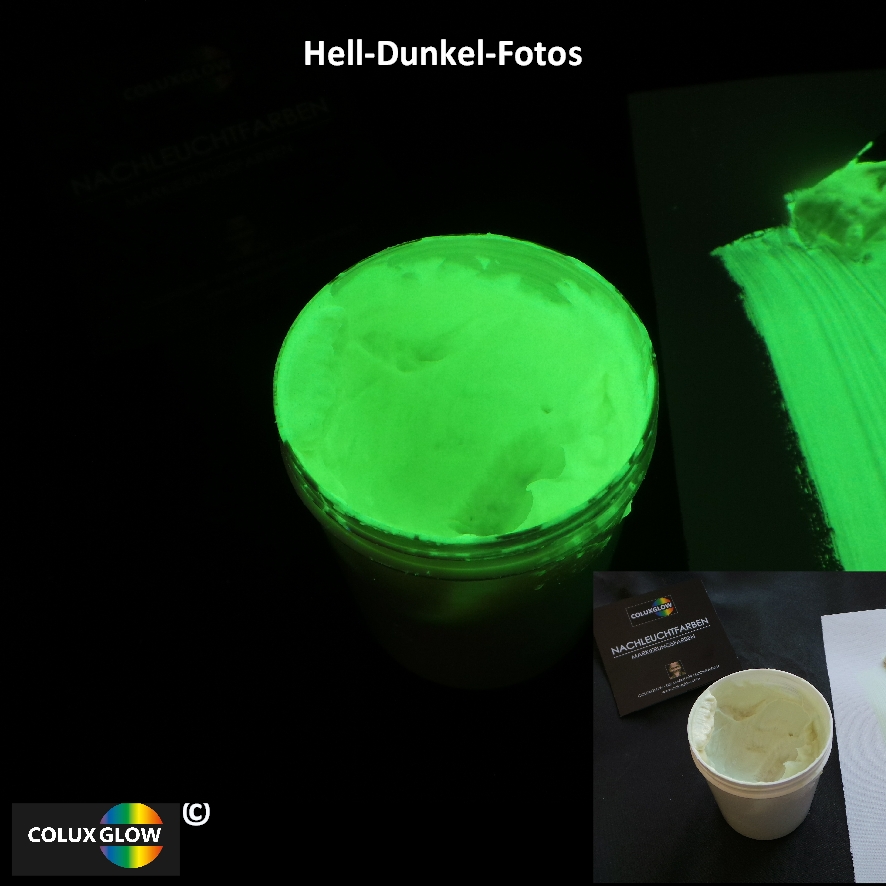

Kurzbeschreibung: Thinner - retarder for artists' paints: Airbrush paint, painting paint, textile painting paint and screen printing inks

Thinner - Retarder for artist colours afterglow

For use in the following ColuxGlow artists' colours afterglow: Airbrush paint - Painting colours - Textile painting colours - Screen printing colours

We recommend the thinner retarder for the afterglow artist colours if the colours have been stored for a longer period of time and thicken a little or if they need an increased flowing property in your printing process. Water is generally not recommended!

0 of 0 reviews

Login

Accessory Items

Content: 0.2 Liter (€97.50* / 1 Liter)

Content: 0.2 Liter (€99.25* / 1 Liter)

Content: 0.2 Liter (€98.75* / 1 Liter)

Content: 0.2 Liter (€97.50* / 1 Liter)

Content: 0.2 Liter (€99.25* / 1 Liter)

Content: 0.2 Liter (€98.75* / 1 Liter)

Content: 0.4 Liter (€99.75* / 1 Liter)

Content: 0.1 Liter (€125.00* / 1 Liter)

Content: 0.2 Liter (€98.75* / 1 Liter)

Content: 0.5 Liter (€93.20* / 1 Liter)

Content: 0.2 Liter (€98.00* / 1 Liter)

Content: 0.2 Liter (€97.50* / 1 Liter)

Content: 0.2 Liter (€99.25* / 1 Liter)

Content: 0.2 Liter (€98.75* / 1 Liter)

Content: 0.2 Liter (€97.50* / 1 Liter)

Content: 0.1 Liter (€125.00* / 1 Liter)

Content: 0.2 Liter (€98.75* / 1 Liter)

Content: 0.2 Liter (€98.00* / 1 Liter)