€49.20*

Available, delivery time: 1-3 days

Kurzbeschreibung: Polyurethane paint 2K for spraying Coating for exterior applications and as one-coat or topcoat in mechanical and plant engineering (exterior)

Application

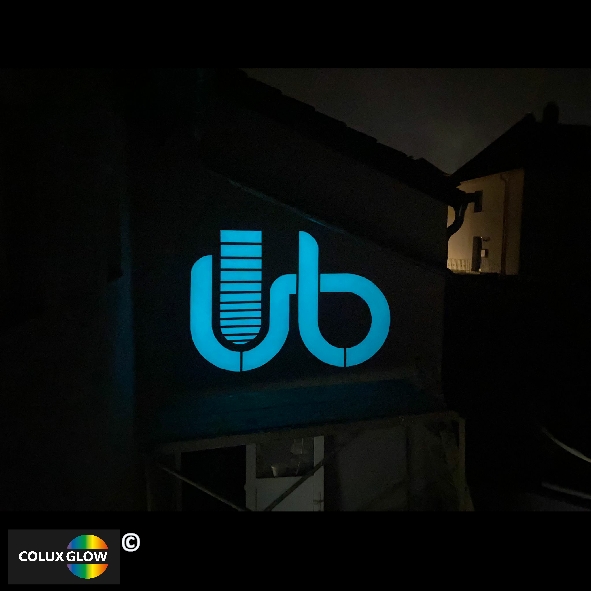

Polyurethane paint 2K coating with ColuxGlow luminescent powder

Afterglow paint can also be applied in thick coats as top coat in multi-layer corrosion protection systems for exterior applications and as single-layer or top coats in machine and plant construction

WHAT CAN COLUXGLOW PAINT DO?

ColuxGlow polyurethane paint with luminescent powder can also be applied in thick layers as a topcoat in multi-layer protection systems for exterior applications and as a single-layer or topcoat in furniture, machine and plant construction - specifically: GRP, PU materials and pre-primed metal surfaces.

BRIEF DESCRIPTION

ColuxGlow polyurethane paint with luminescent powder is based on an OH-functional acrylic resin which is cross-linked by means of an aliphatic hardener (polyisocyanate adduct).

APPLICATION

■ The mixing ratio is taken into account in the pack sizes. The mixtures must be completely homogenized. We recommend using a stirrer to prepare the mixture and using a mixing container with a volume of approx. 1 L for this purpose.

■ Mix

1. Step: add binder and hardener - 3 min mixing time

2. Step: add powder - 3 min mixing time

3. Addition of 5-10 % universal thinner required!

■ Storage of finished mixtures beyond the specified pot life 4-6 hours is not possible.

■ TIP: Add thinner 40 gr. for brushing to 80 gr. for spraying!

NOTE

2K Binder Contains : Hydrocarbons,C9,Aromatics ; CAS No. : 64742-95-6; Reaction product of decanoic acid, 12-hydroxystearic acid and 1,2-ethanediamines React.mass: bis(1,2,2,6,6-pentamethyl-4-piperidyl)sebacate and methyl1,2,2,6,6-pentamethyl-4-piperidyl sebacate Attention

SPECIFICATION

| FUNCTION | Spray paint for luminous objects | |

| COLOUR TONE | yellow-green or blue luminescent | |

| DENSITY | 1,2 kg/L adjustable with thinner | |

| LAYER | 50-100 my dried film | |

| COMPONENTS | 470 gr. base component G + 60 gr. hardener AL-17 + 270 gr. illuminating powder gives 800 gr. mixture 2:1 |

|

| APPLICATION | Drip time 4-6 hours at 20-24 degrees C Universal thinner commercially available | |

| SPRITTABLE | Cup gun with agitator | |

| PROCESSING | Drying temperatures at 10°C, Humidity above 85% or insufficient air movement, the drying times increase considerably. |

|

| DRYING TIME | DUST DRY | 1 hour |

| GRIP SOLID | 3 hours | |

| WATERPROOF | 24 hours | |

| PACKAGING | 0,8 kg portioned see components | |

| SHELF LIFE | Components separately in unopened Original containers at Storage temperatures between 15 and 25°C for at least 6 months. Storage temperatures above 25°C are to be avoided, |

|

SPEZIFIKATION

| FUNKTION | Sprühlack für Gegenstände die leuchten | |

| FARBTON | gelbgrün bzw. blau bzw. türkis nachleuchtend | |

| DICHTE | 1,2 kg/L einstellbar mit Verdünnung | |

| SCHICHT | 50-100 my getrockneter Film | |

| KOMPONENTEN | 470 Gr. Stammkomponente G + 60 Gr. Härter AL-17 + 270 Gr. Leuchtpulver ergibt 800 Gr. Mischung 2:1 | |

| ANWENDUNG | Tropfzeit 4-6 Stunden bei 20-24 Grad C Universalverdünner handelsüblich | |

| SPRITZBAR | Becherpistole mit Rührwerk | |

| VERARBEITUNG | Trocknungstemperaturen unter 10°C, Luftfeuchtigkeit über 85% oder ungenügender Luftbewegung erhöhen sich die Trockenzeiten erheblich. | |

| TROCKENZEIT | STAUBTROCKEN | 1 Stunde |

| GRIFFEST | 3 Stunden | |

| WASSERFEST | 24 Stunden | |

| VERPACKUNG | 0,8 kg portioniert siehe Komponenten | |

| LAGERFÄHIGKEIT/HALTBARKEIT | Komponenten getrennt in ungeöffneten Originalgebinden bei Lagertemperaturen zwischen 15 und 25°C mindestens 6 Monate. Lagertemperaturen über 25°C sind zu vermeiden, | |

Login