Product number:

SW10066

Kurzbeschreibung:

Product information "Coluxglow test certificate DIN 67510 for photoluminescent markings"

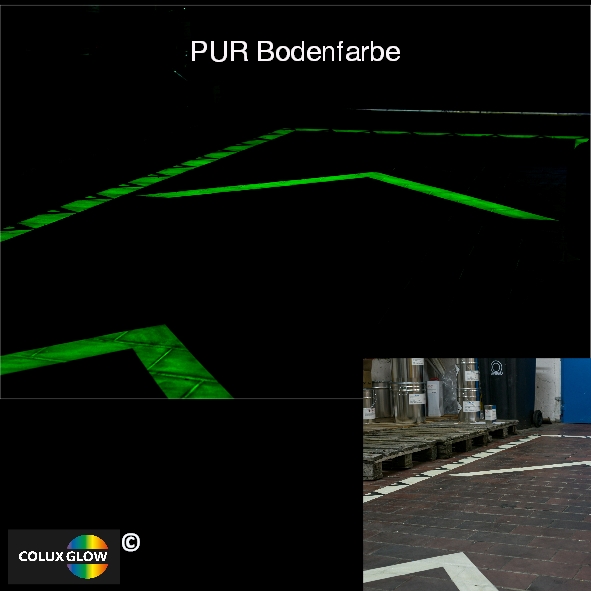

Field of application

Test certificate based on the DIN 67510 standard for photoluminescent markings

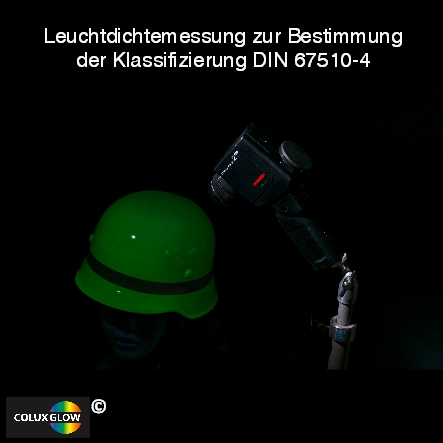

Test certificate of the luminance measurement from the product standard for photoluminescent markings

Creation of a test certificate from a laboratory order in accordance with DIN 67510-4 with the values of the luminance measurement and luminous duration determination for photoluminescent markings.

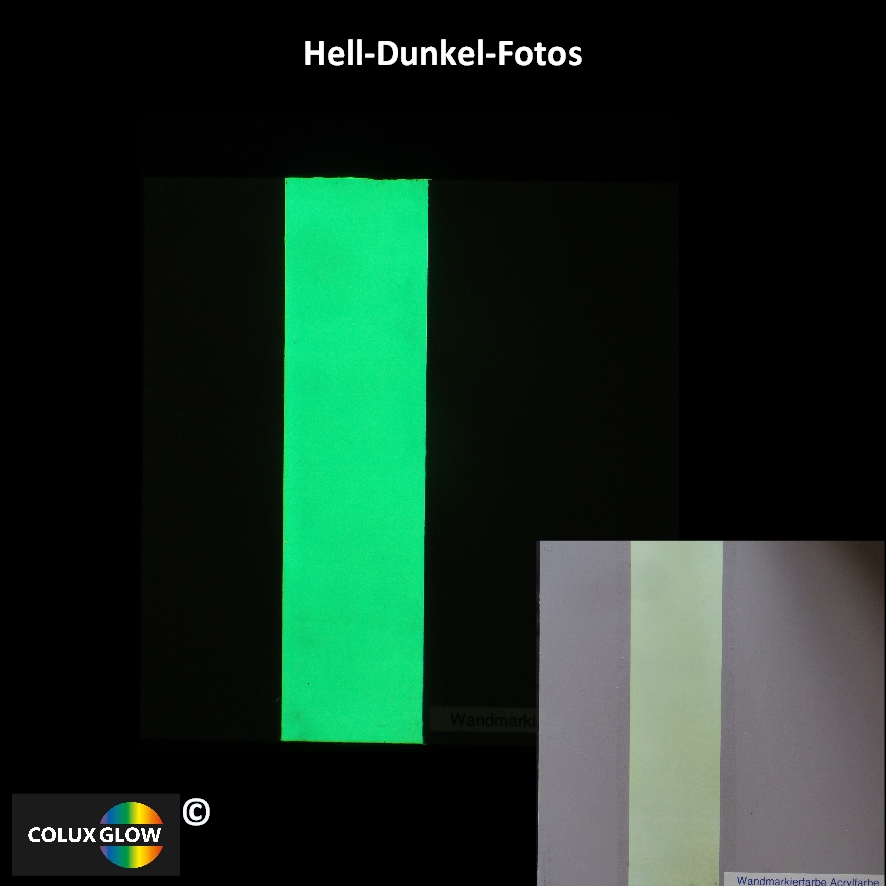

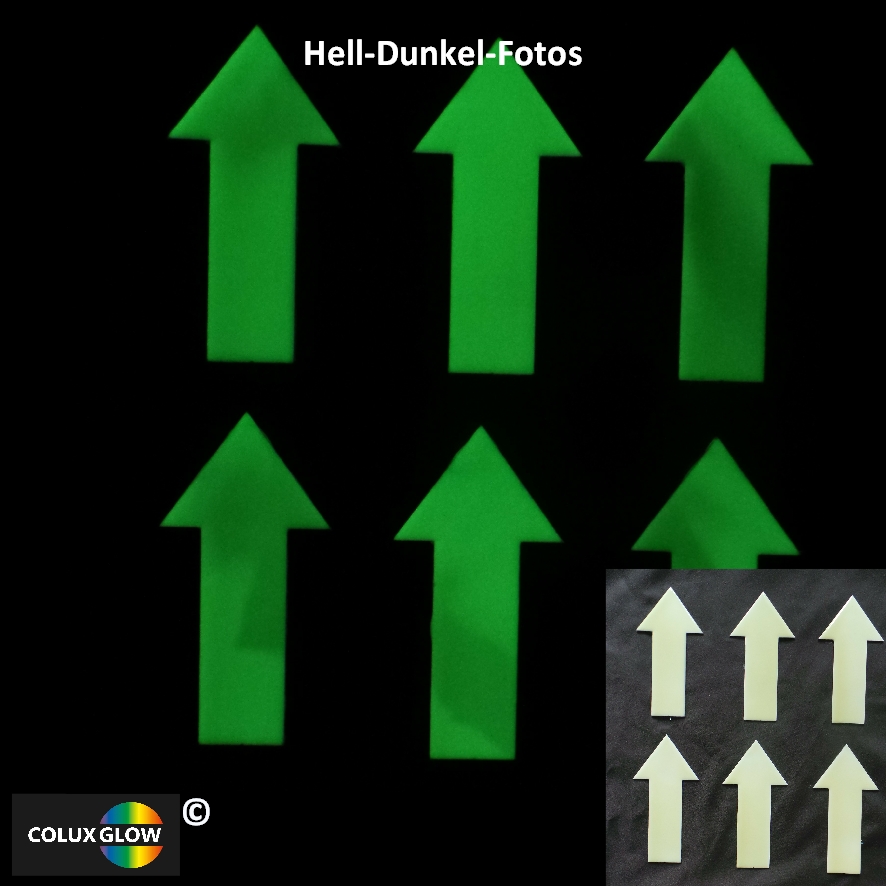

The photoluminescent products tested in this way show the results in relation to the specifications of ASR A3.4/7 and DIN 67510-4 Class B or C and can be assigned accordingly.

- ASR A3.4/7 : Workplace safety

- Class B: For better orientation on escape and rescue routes in the dark

- Class C: If no sufficient safety lighting is available as well as for the installation of photoluminescent markings for optical safety guidance systems.

Type and scope of service

- Scope of services: Testing of the reset pattern from the standard or from the special design.

- Additional service: Testing of one of the customer's objects that you make available to us for measurement.

Login